Projects

Fabrication

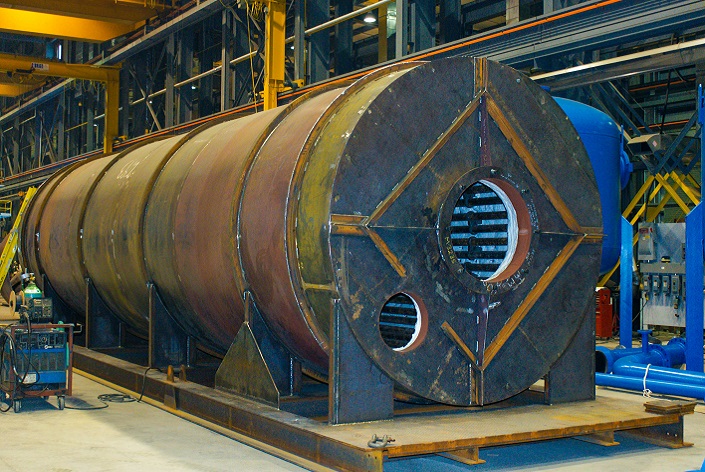

Ferric Sulphate Reactor

15-foot diameter Ferric Sulphate Reactor with Alloy 20 material with Dimple Jacket completed for shipment to Texas, USA. Pressure Vessel built to very specific specification and ASME Section VIII Div. I with National Board Registration.

Stainless Steel Pressure Vessel

Stainless Steel Pressure Vessels with half Pipe Jacket designed and fabricated to ASME Section VIII Div. 2 for Cyclic Services with Fatigue Analysis. These Vessels were registered with the National Board and shipping to the USA.

Wall Vessel

Large Diameter Heavy wall vessel being transported on barge. This Vessel was provided with corrosion resistant interior lining. Pressure Vessel Construction to ASME Section VIII Div. I with CRN for Ontario.

Boilers

High Pressure steam Generator

Once through 2850 PSI 700F high pressure steam generator ready to be painted. Built to ASME Section 1

Super Heater Repairs

On each of 3 Central Utility Boilers separately remove the existing Super Heater, shop fabricate 54 new Super Heater elements from SA213 TP T11, each complete with support brackets deliver to site and install.

Note no OEM drawings were available, all detailed design and engineering was determined at start of shut down and we were able to complete within predicted schedule.

The project was executed safely on time and on budget. SBWW utilized in house orbital welding and rotary tube bending to both increase productivity and maintain a high level of quality. Of all welds performed in shop and in situ there were Zero repairs required.

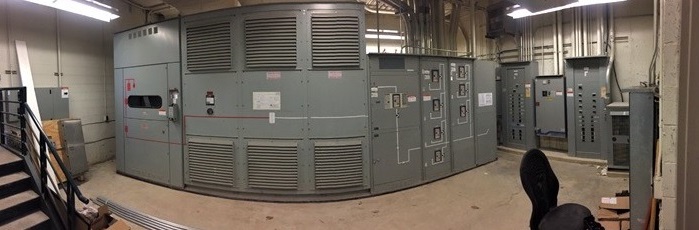

Electrical

Before

After

Main Transformer & Genarator Upgrade

Client: NIAGARA COLLEGE CANADA

Project Desription

- Craning/rigging and removal of old equipment from Generator Room and Electrical Room.

- Supply and installation of 500kW Diesel Generator and two (2) Automatic Transfer Switches

- Supply and installation of 27.6kV/600V/3500kVA Transformer and New High Voltage Load Break Switch.

- Supply and installation of 4000A/600V Main Switchboard and Custom 4000A Bus Duct.

- Modification of existing Electrical Room for the installation of New Transformer.

- Supply and installation of fans, ductwork, insulation and HVAC controls.

- Phased switchover from old to New Transformer infrastructure. This shutdown included four (4) 24 hour shifts to remove all existing Electrical Distribution and install New Upgraded Electrical Power Distribution System.

- Equipment Start-up and Commissioning.

Before

After

Emergency Generators Replacement and Cooling Tower Upgrade

Client: NORFOLK GENERAL HOSPITAL

- Removal of two (2) Indoor Emergency Generators, 500kW and 250kW prime rated, including Diesel Fuel Tanks, Pumps, Venting, Power and Control Wiring.

- Supply of two (2) Temporary Generators connected to the existing two (2) Transfer Switches to provide Emergency Power to the Hospital during construction.

- Installation of two (2) 600kW prime rated Enclosed Outdoor Standby Diesel Generators complete with emergency power distribution and controls.

- Supply and installation of two (2) new 800A-600V Automatic Transfer Switches complete with Dual Bypass and Closed Transition.

- Modifications to existing Main Incoming Distribution Panelboard including installation of New Eaton Custom Distribution Center for paralleling additional Generator Power to Building normal power loads to the Hospital.

- Installation of New Cooling Tower complete with all piping, supports, electrical, controls, structural steel frame and roofing.

- Installation of Fire Alarm System complete with Control Panel for monitoring of New Generators.

- Construction of Lifting Plan showing the layout of 350T Crane with step-by-step description of the work.

- Provided detailed procedures and durations on various sequenced shutdowns to the Hospital.

- Owner Training, Start-up and Commissioning for all major equipment

Project Desription

Before

After

OUTDOOR TRANSFORMER & SWITCHBOARD REPLACEMENT

Client: TAYLOR STEEL

- Trenching, supply and installation of crushed stone and perforated drainage piping below cable bus system.

- Supply and installation of transformer concrete vault, grounding rods and ground grid.

- Installation of two (2) 600kW prime rated Enclosed Outdoor Standby Diesel Generators complete with emergency power distribution and controls.

- Installation of new 2000kVA outdoor pad mounted transformer 27.6kV/16kVPrimary,Secondary 480V/277V

- Coordination on high voltage poles/lines and secondary metering for new service.

- Supply and installation of Maxi-Amp Secondary underground cable bus system complete with precast concrete trench and 3200A rated single conductor cables.

- Multiple crane lifts for installation new transformer and removal of the old transformer.

- Installation of new 480V, 3200A switchboard c/w main breaker, utility metering compartment etc.

- Remove all building loads for existing main switchboard and modify as required all existing cable trays/Teck/Coreflex cables to new switchboard. This was done over the Labour Day Long weekend.

- Decommissioning of old outdoor substation including high voltage cable/structure/grading and site resoautation including disposal of oil filled transformer with all associated paper work.

- Removal of old 4000A main switchboard.

- Cover all openings with metal sheeting

- New electrical room door, cladding and floor openings shown on structural drawings.

Project Desription